Tips

The tip is a fundamental component and the one most subject to wear of the plasticizing unit. Its tightness guarantees the correct flow of the material and the repetition of the process.

The most relevant features are:

• Avoid stagnation points

• Avoid flow restrictions

• Allow a perfect seal with the cylinder

• Ensure good durability over time

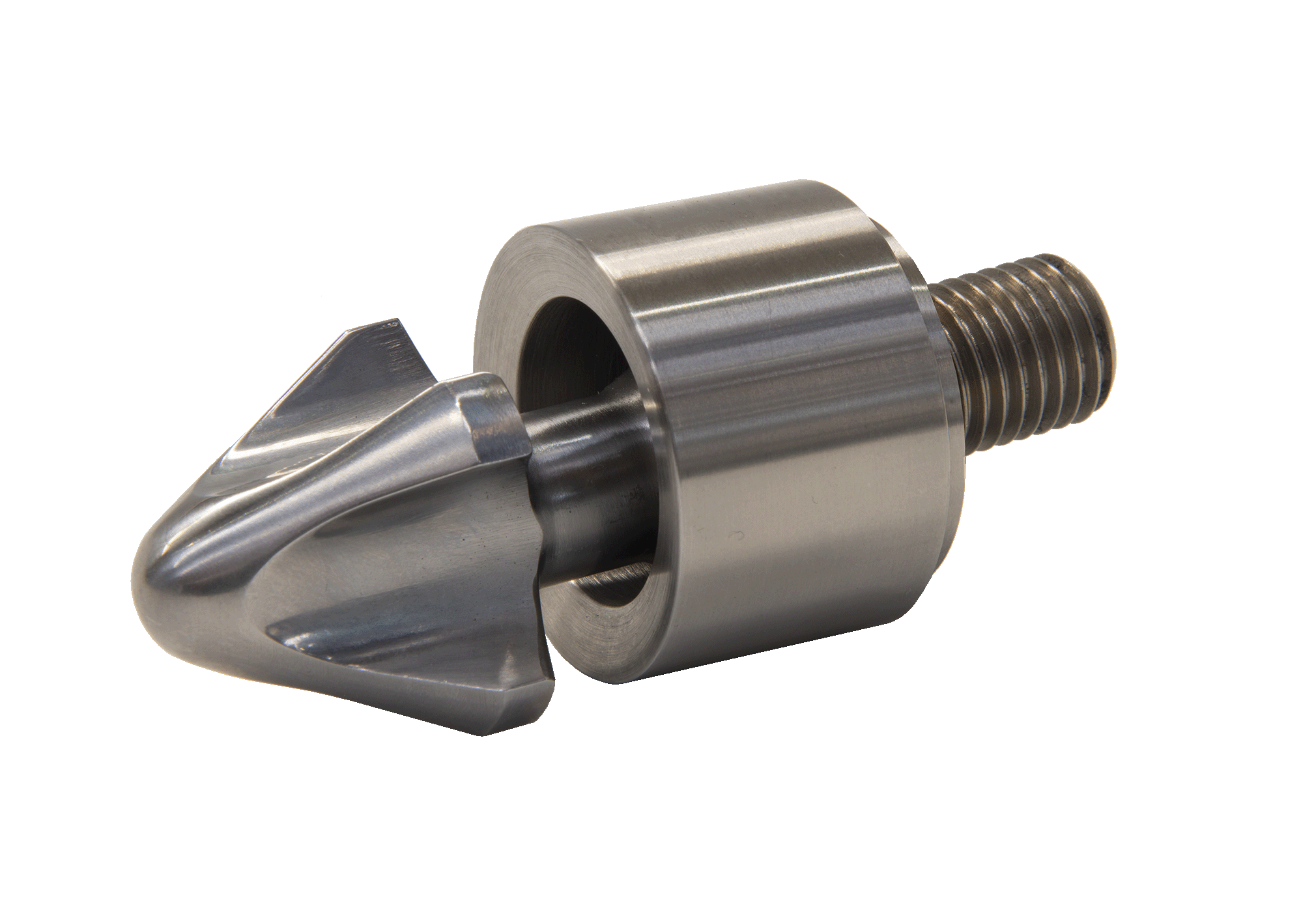

Standard tip

The most traditional and versatile solution, consisting of body, valve and washer, ideal for any type of molding.

Mixing tip

Solution that helps to improve the mixing and dispersion of dyes without pressure loss.

Ball tip

Ideal solution for screws with large diameters (generally d.80 mm) as it guarantees a better closure, as well as favoring the alignment of the screw-ferrule group.

Anti-rotation tip

Design where the valve rotates together with the tip over and move on the horizontal axis as it is locked between the fins of the tip itself.

Quick closing tip

Design that allows greater control over valve closure, faster and more precise , suitable for applications with very fast cycles or excessively liquid polymers.

Coatings

| MATERIAL | TECHNOLOGY | COEF. FRICTION | THICKNESS | HARDNESS | COLOR |

|---|---|---|---|---|---|

| CroX | PVD | 0,3 | 2 – 5 µm | 2000 – 2500 HV | rainbow |

| TiN | PVD | 0,45 | 2 – 5 µm | 2000 – 2500 HV | gold |

| I open | PVD | 0,35 | 2 – 5 µm | 2800 – 3000 HV | grey |

Materials

TOE VT100

The tip body is made of 1.6510 material with BoroTec 10009 coating on the fins, while the valve and the washer are made of hardened steel. This solution, however standard, is versatile and adaptable also to technical polymers, in the absence of high wear.

TIP M390

Tip, valve and washer are made of steel synthesized by powder metallurgy. This is the best solution to ensure a longer duration over time especially in those applications that involve extreme wear, both corrosive and abrasive.

TIP HA8

The body of the tip is made of 1.6510 material with tungsten carbide-based coating on the fins, while the valve and the washer are in hardened steel with high hardness. The addition of a PVD coating allows to have an ideal solution for large diameters especially in those applications that involve high wear.