Summer Closure 2024

Si informa che Brixia Plast resterà chiusa da sabato 10 agosto a domenica 1 settembre. Per qualsiasi esigenza potete scrivere un'e-mail a info@brixiaplast.it ...

Christmas festivities

The holiday season is fast approaching, and with it the end of the year is also imminent. For Brixia Plastthis year has been full of changes that have led the company toward great growth in terms of...

PLAST 2023

In a world that is increasingly attentive to environmental impact, Brixia Plast presents itself as an avant-garde company in the plastic material transformation sector. Finally after a...

New Cooperation Between Brixia Plast and Haitian International

Innovation as the cornerstone for development: Brixia Plast as preferential aftermarket supplier to Haitian International in Europe. Brixia Plast is proud to announce that an important contract has...

Our service

Our service is ready to respond to every need quickly while maintaining a consistently high standard. By relying on Brixia Plast, the user can get a complete 360-degree service and advice. From...

Innovation, design and efficiency

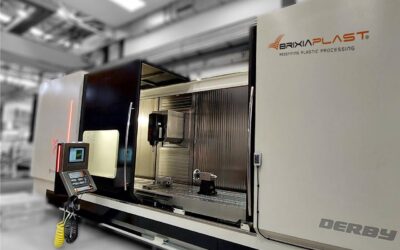

Innovation, planning and efficiency are the pillars that have guided for years Brixia Plast in pursuing their own goals and those of our buyers. Our business is constantly evolving, and our many...

Workshop “MELTING PROCESS INNOVATION”

We are pleased to invite you to participate in the last "MELTING PROCESS INNOVATION" Workshop of this season. Which will take place on October 7-8 at the.farmhouse "Cascina Carretto". The two days...

Green module: a green response.

Nowadays there is an increasingly pressing need to create a marriage between stringent new regulations regarding environmental protection and respect and the need to implement productivity, lowering...

Brixia Plast at Messe K in Düsseldorf

Once again this year Brixiaplast will be participating in Messe K in Düsseldorf, one of the most important information and trade platforms for the global plastics and rubber industry. During this...

SERVICES

DISASSEMBLY

The staff and complete equipment of the assistance department allow you to dismantle any laminating unit quickly.

CLEANING

A latest generation pyrolytic oven allows the components of the plasticizing unit to be cleaned from plastic residues, in compliance with the most advanced environmental regulations.

DIMENSIONAL CHECKS

Complete checks are carried out on the customer’s components, to verify the state of wear and to detect any problems. These checks can also be carried out on customers’ premises by qualified personnel.

REVISIONS

The overhaul of the laminating units responds to the need for cost containment and speed, but at the same time requires solutions capable of guaranteeing optimal performance.

The quality of a company is measured by the numbers that really matter!

… and these are the numbers from Brixia Plast.

Plastification Screws and Cylinders

SQUARE METERS OF PRODUCTION AND OFFICES

MECHANICAL DRAWINGS MADE AND ARCHIVED

CUSTOMERS SERVED WORLDWIDE

ISO 9001 certification

BRIXIA PLAST QUALITY

Rapid technological progress and market globalization have made quality management oriented towards production processes a necessity as well as a challenge for our companies.